Our facilities

A design office and a production unit in France

MEODEX consists of a Design office and a Production unit.

Our facilities are located in Narbonne, France, with a production installation of 500 m2.

This surface allows us to house our production lines, testing facilities and storage units.

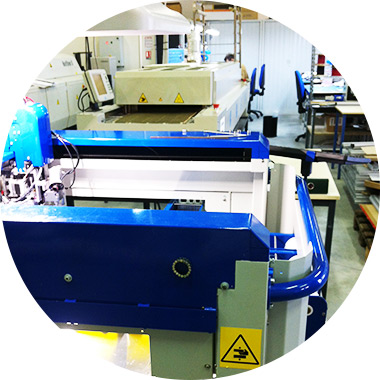

Assembly line allowing us to adapt to any requests

With our three types of production lines, we are able to adapt to a wide variety of projects:

– 100% Manual Production Lines: they allow us to have a high responsiveness on small series, prototypes or control productions prior to launch large scale production.

– Semi-automatic lines authorize us to take in charge medium quantity series. Indeed, the mechanization on specific tasks and our high responsiveness enable us to reduce unit costs

– Fully automatic lines enable us to manage large-scale projects (> 200 000 cards per batch). Unit costs are optimized.

Stock management of our client’s subassemblies

We also have the necessary means to ensure the stock management of our client’s subassemblies. This allows them to reduce sourcing costs through an optimized supply, as well as the processing time of their order. This practice is greatly advantageous when operating with a tight workflow.

Shaping Cables

Shaping cables workshops ensure us to offer the following services: cutting wire, stripping and pre-stripping, tinning, crimping and soldering of wires on boards. These additional services have the advantage of allowing us to handle the assembly of prototypes as a whole, and also to limit the number of stakeholders in the production of LED modules.

Test and Measurements

Through testing and measurement workshops we ensure the testing of all cards we produce. Also, thanks to these materials we can ensure by ourselves the after-sales service, and these returns feed our experience of development and production.